|

Getting your Trinity Audio player ready...

|

PRESS RELEASE. From Deragger Case Studies website. on Sewer Authority Mid-Coastside, published in February, 2018.

Problem: Frequent ragging at a pump station took a lot of staff time to clear pumps and caused less than optimal operation overall.

Solution: Installing an anti-ragging device prevented clogging and allowed rags t o pass through impellers and be removed by screens.

o pass through impellers and be removed by screens.

One of the pump stations owned and operated by the Sewer Authority Mid-Coastside (Half Moon Bay, Calif.) suffered from frequent ragging. Pump ragging, often caused by improper disposal of nonwoven and fibrous materials, is an expensive problem that plagues the water sector.

In total, the sewer authority owns and operates a sanitary wastewater treatment facility, three pump stations, and a collection system that collects wastewater from a satellite collection systems. These facilities serve the City of Half Moon Bay, the Granada (Calif.) Community Services District, and the Montara (Calif.) Water and Sanitary District.

Ragging costs money and time

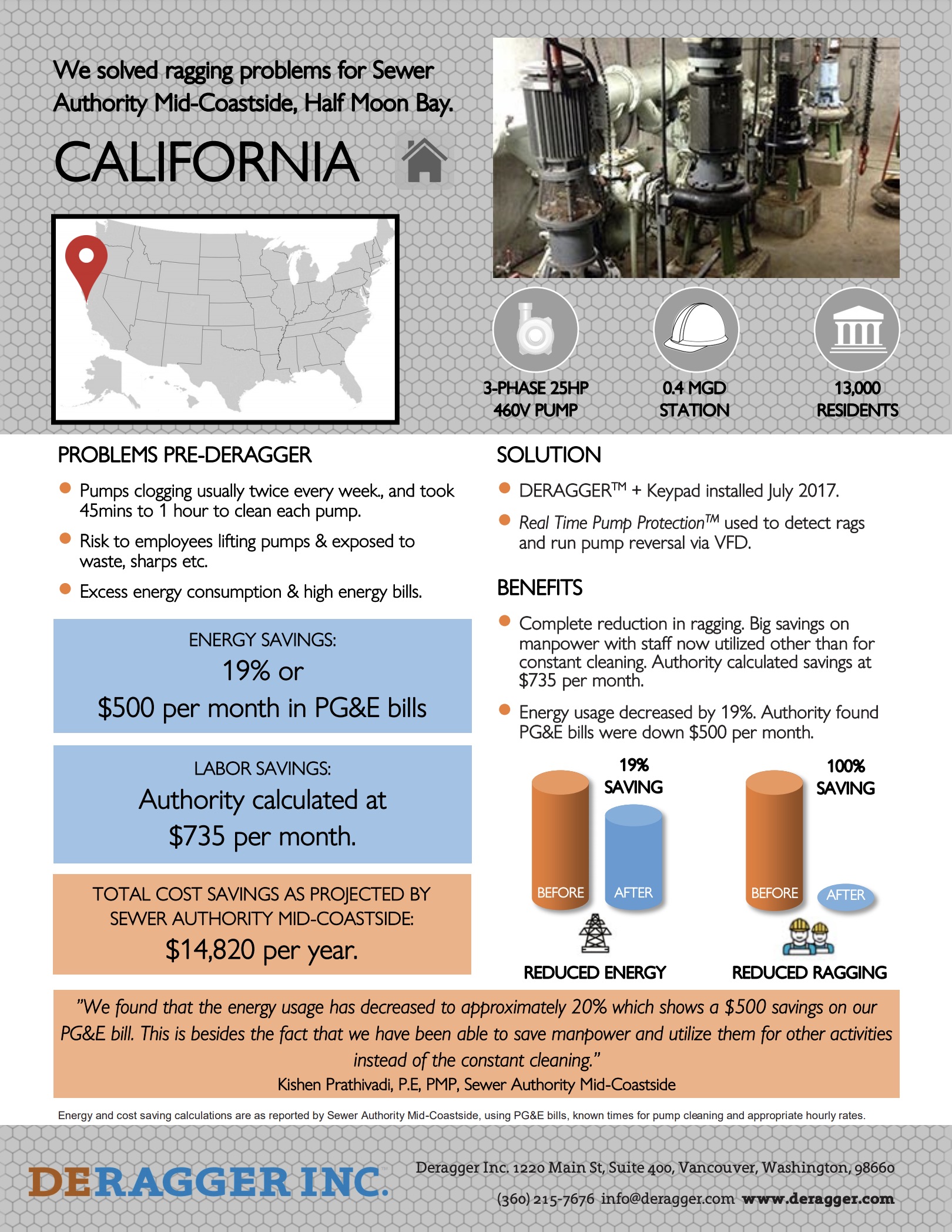

The clogging at one of the pump stations occurred twice a week. For each clog, operators spent about 1 hour lifting and cleaning the pumps. The process cost money as well as employee time, diverting staff away from other required duties. Lifting and cleaning pumps also put staff welfare at risk through exposure to untreated wastewater and any needles or sharps in the waste.

Even when the pumps were not fully obstructed, they were running partially ragged, which affects efficiency. When a pump runs with rags caught on the impeller, flow rate, run time, variable-frequency drive speed, and power consumption all suffer. This causes stations to operate very differently from design parameters.

But just installing chopper or grinder pumps to address the problem can shift the problems from the pump station downstream to the treatment facility. The small particles produced by grinding pass through screening at the headworks in the treatment facility. Grinder and chopper pumps also are costly in terms of maintenance.

Detection allows the problem to pass

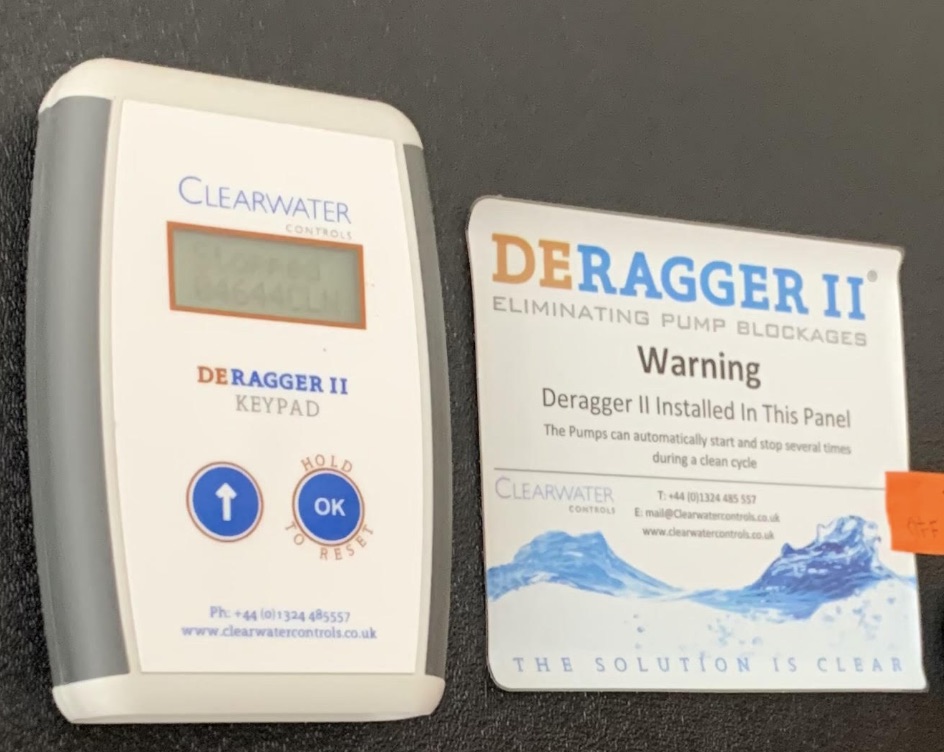

The sewer authority learned about a new piece of technology called the DERAGGER™. This system is designed to prevent ragging while improving efficiency. The anti-ragging device detects rags that reach the impeller prior to a full obstruction forming.

In July (2017), the sewer authority decided to install one of these units. It uses Real Time Pump Protection™ technology that monitors the power signature of a pump’s motor for fluctuations in the three-phase waveforms. When some rags get caught on the impeller, the device modifies pump behavior to allow the rags to pass through rather than letting them weave into an obstruction over time.

Because individual rags pass through whole, rather than in pieces, no tiny particles are created to flow downstream and cause other issues. The technology also helps extend the lifespan of pump components. It can detect such issues as advanced bearing- or seal-wear and alert the owner prior to equipment failure. This warning increases the ability to plan for maintenance needs.

Smooth flowing results

The installation eliminated pump ragging at this pump station. The pumps now pass the rags along to the treatment facility’s screens. With manual cleaning eliminated, staff no longer are exposed to wastewater or sharps. The system also has given the sewer authority a $500 saving every month in electricity consumption.

“We found that the energy usage has decreased approximately 20%,” said Kishen Prathivadi, professional engineer and project manager (now General Manager) at the sewer authority. “This is beside the fact that we have been able to save manpower and utilize staff for other activities instead of the constant cleaning.”

The sewer authority estimates that the total savings in the first year, from redirected staff time and energy savings, will amount to $14,820. This will result in a return on investment in a few months. ■

Deragger.com

Sewer Authority Mid-Coastside (SAM) Meetings ~ 2nd & 4th Mondays @ 7:00pm

Watch remotely. Comments and questions by email.

Agendas and Zoom Links

SAM Meeting Videos via Pacific Coast TV

Contact Us

Our regular office hours are 7:00 a.m. through 4:00 p.m., Monday through Friday, excluding holidays.The Authority can be reached 24-hours a day at:

(650) 726-0124

Our Mailing Address is:

Sewer Authority Mid-Coastside

1000 Cabrillo Hwy N.

Half Moon Bay, CA 94019

Yellow = cancelled SAM meeting due to Holidays

(650) 726-7833 (fax)

Regular Board Meetings are on the 2nd and 4th Mondays of each month at 7:00pm.

From time to time a meeting date may be changed, cancelled or relocated. Check the posted agenda for any changes to the normal schedule (click on links below).

The Sewer Authority Mid-Coastside (SAM) provides wastewater treatment services and contract collection maintenance services for a population of approximately 27,000 in the following areas:

- City of Half Moon Bay

- El Granada

- Miramar

- Montara

- Moss Beach

- Princeton by the Sea

Barbara Dye

Chair, Representing Granada Community Services District

Deborah Ruddock

Vice-Chair, Representing the City of Half Moon Bay

Kathryn Slater-Carter

Secretary/Treasurer, Representing Montara Water and Sanitary District

Dr. Deborah Penrose

Director, Representing the City of Half Moon Bay

Ric Lohman

Director, Representing Montara Water & Sanitary District

Matthew Clark

Director, Representing Granada Community Services District